The Supply Chain

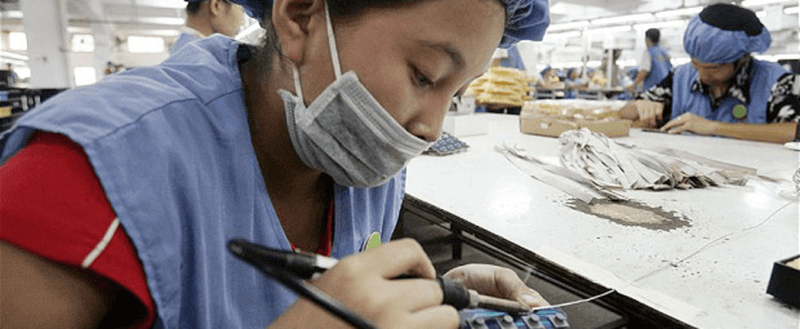

There has been a great deal of media interest in the idea that manufacturing in China is starting to become less appealing to Western companies. There has been speculation that wage cost advantages will gradually erode and that perceptions of poor quality and business environments will drive production back home.

What this speculation fails to take into account, however, is one of the main advantages that China holds; something which is unaffected by any of these factors – the proximity of the supply chain. What many people think of as ‘manufacturing’ is more along the lines of assembly – the individual components are manufactured separately, possibly in many different factories, and then assembled into the finished product by another manufacturer.

It’s not just assembly work that has been outsourced around the world; it’s also the individual component production. Now, it’s true to say that not all of that production has moved to China, but it’s also worth recognizing that the vast majority of components are produced in Asia. South Korea and Taiwan have made big gains based on successful production of components and even countries like Thailand and Malaysia have started to get in on the act.

China also has many factories dedicated to component manufacture and this is where one of the key advantages comes from for Chinese companies. If manufacturing moves back to the West, it means that assembly will move back first. This puts Western organizations at a huge disadvantage, particularly in the United States, because it places them a long way from the companies that will make the components for their products.

In terms of production times, this may be a fatal error. If a Shenzhen based manufacturer buys its components locally and there’s a problem, it’s easy to instigate return processes. It’s also cheap in terms of logistics as the goods don’t have to move very far to be returned. A face-to-face meeting enables problems to be overcome quickly with the minimum amount of disruption to the deadlines for delivery.

For an American manufacturer they’ll need to be able to communicate at a local level with their component providers and deal with all of the associated language and cultural barriers. Then they’ll need to ship their returns overseas back to Asia (which is expensive and time consuming in itself). They’ll have to hope that the supplier understands their issue and is willing to remedy it quickly, which they may or may not be willing to do without a whole heck of encouragement. And then they have to wait for the next shipment to arrive – costing more time, more money – before they can test to see if the problem has actually been resolved.

Another factor to consider is that the wage differentials aren’t as close as those reported in the media. The figures for median and average wages in Chinese manufacturing aren’t anywhere near as high as those shown in some of the figures claimed in Western media. But even if they were, Chinese manufacturers have a serious competitive edge in their proximity to the supply chain – one that the West would need decades to overcome.

So the bottom line is, don’t bet the farm on a manufacturing exodus from China any time soon.

SZCEIT can help you come to an understanding of how manufacturing your products in China can save you time and money while maintaining the quality your customers have come to expect from your brand.